Power of an echelle grating relative to that of a conventional blazed grating in the Littrow mode is given by The resolvingįIGURE 3.5 Efficiency of an 1800-grooves/mm ruled grating Albert Michelson, who referred to them as echelons, discovered echelle gratings in 1898. Echelle gratings are generally used with a second grating, or prism, to separate the overlapping diffraction orders. The resolving power of an echelle grating used in the Littrow mode at the blaze angle is proportional to the tangent of the large blaze angle. They are coarsely ruled (large d) blazed gratings with a large blaze angle. Figure 3.5 shows typical diffraction efficiency of a 500-nm blazed ruled diffraction grating with 1800 grooves/mm.Įchelle gratings are used for high-resolution spectroscopy.

For this value of d, the value of λ B is 0.5 μm or 500 nm.ĭiffraction efficiency η of a grating depends upon the wavelength of light and its polarization, relative to the grooves of the grating. For example, if there are 1800 grooves/mm, the value of d is 5/9 um. In this case, the grating equation becomesįor m = 1, the blaze wavelength is given byįor many commercial gratings, the value of sin γ is equal to 0.45, corresponding to γ = 26☄5′, so that λ B is equal to 0.9d. Figure 3.4 shows a blazed reflection grating with triangular groove facets, which are at an angle γ (called the blaze angle) with the grating surface.įor θ i = γ ,most of the diffracted energy goes in the direction of the specular reflection from the groove facets, which corresponds to θ m =-γ. Such gratings are referred to as blazed reflection gratings. Grooves of a diffraction grating are usually shaped to obtain most of the diffracted energy in a given order m for the desired wavelength λ. The removed film is then attached to a substrate.The groove density in the replica is somewhat higher than that in the original grating because of shrink-age of the replica. Replica gratings are made by pouring a plastic solution over an original grating, evaporating the solvent, and removing the resulting film, which has the grooves of the original grating impressed upon it (Wallace 1905). Because aluminum is fairly soft, it causes less wear on the ruling diamond tool.Ĭommonly used ruled diffraction gratings are the relatively inexpensive metalized replicas of the master diffraction gratings. Contemporary gratings are ruled in thin films of aluminum evaporated on optically flat glass blanks. Harrison’s design has become standard practice in modern ruling engines. Harrison and his team equipped their engine with interferometric position feedback control (Harrison and Stroke 1955). Harrison’s laboratory at Massachusetts Institute of Technology in 1947. One of Michelson’s engines later ended up in Prof. Michelson was able to produce gratings as large as 10 inches. Rowland engines were capable of producing gratings as large as 7.5 inches.

GRATING DIFFRACTION ANGLE SERIES

Rowland and his successors at the Johns Hopkins University designed and implemented a series of ruling engines, each superior to its predecessor. In 1882, he ruled gratings of 6-inch widths with more than 100,00 grooves and resolving power in excess of 1.5×10 5 (Harrison 1949). Rowland is considered to be the father of modern ruled diffraction grating. Master diffraction gratings are ruled with mechanically controlled ruling engines.

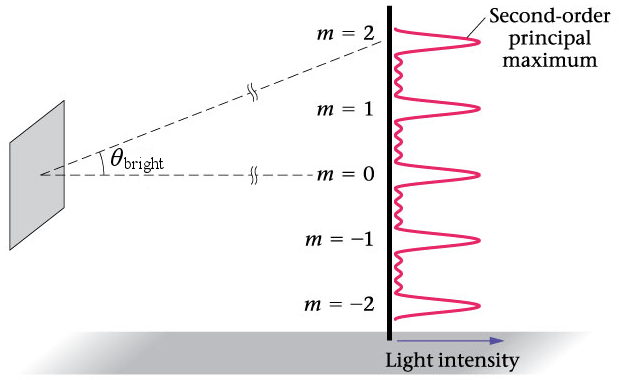

To determine the number of diffraction orders recall that -1 ≤ sinθ m ≤1. Θ m, is the angle of diffraction for order m that is equal to 0, ☑, ☒, and so on Light incident upon a grating is diffracted according to the grating equation Holographic and dielectric gratings are produced using photolithography. Diffraction gratings for optical spectroscopy are made by ruling grooves either on a transparent surface to obtain a transmission phase grating or metal surface to obtain a reflection phase grating. The multiple-slit assembly is a transmission amplitude grating. David Rittenhouse, an American astronomer, produced the first diffraction grating around 1785 as a multiple-slit assembly consisting of fine wire. A diffraction grating is an optical component with a periodic structure, which produces periodic changes in the phase, amplitude, or both, of a monochromatic or polychromatic light beam incident upon it.

0 kommentar(er)

0 kommentar(er)